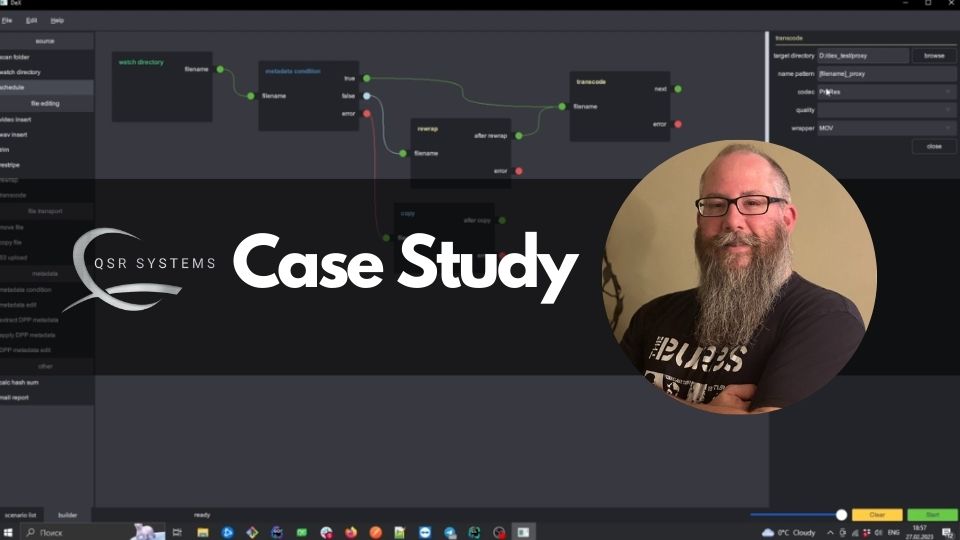

Cinedeck Case Study: QSR Systems

Cinedeck’s ConneX workflow engine allows QSR Systems to optimise workflows to create streamlined production processes that are faster and flexible, saving time and money to meet the increased demand for content output.

Objective

Founded in 1991, QSR Systems are the leading west coast provider of post-production edit and storage systems, offering a wide range of transcoding and editorial solutions for media providers, broadcasters and post-production houses in the industry. Among these solutions is Quick-Lab, the extensive and integrational transcoding lab solution that allows for increasing freedom and streamlining at every stage of the post-production workflow. As a long time Cinedeck collaborator and user, QSR developed its already existing Cinedeck foundation with the integration of new tools and features.

Watch the ConneX webinar below:

Solution

Cinedeck provided a solution, in collaboration with QSR, allowing for a fully flexible and streamlined post-production workflow inspired and constructed by ConneX, showcasing the following features:

- Direct fibre connections and fast upload speeds, provided by QSR and enhanced by integration with Cinedeck solutions.

- The integration of ConneX, Cinedeck’s flexible and scalable media processing platform for automated post-production workflows.

- Trim, Re-Wrap and Transcode functions for an integrated and streamlined workflow.

- Natively supported codecs for simultaneously created editorial quality metadata files.

- Live files available immediately in all standard edit suites, remote or on-prem.

Benefits

- Pop up systems available wherever the editor is located, reducing resources for transporting people and equipment to on-prem post-production locations.

- The Quick-Lab workflow has universal application, entirely customisable and scenario-specific for the needs of an individual production.

- Automated workflow tasks moved to earlier in the process, reducing human error and need for tedious and repetitive tasks.

- Entirely optimised and streamlined workflow from ingest to delivery.

- Flexibility in-solution to recognise and accommodate for outdated products and approaches as well as new turn-key solutions and features.